-

E-mail: scfpumps@gmail.com

Products

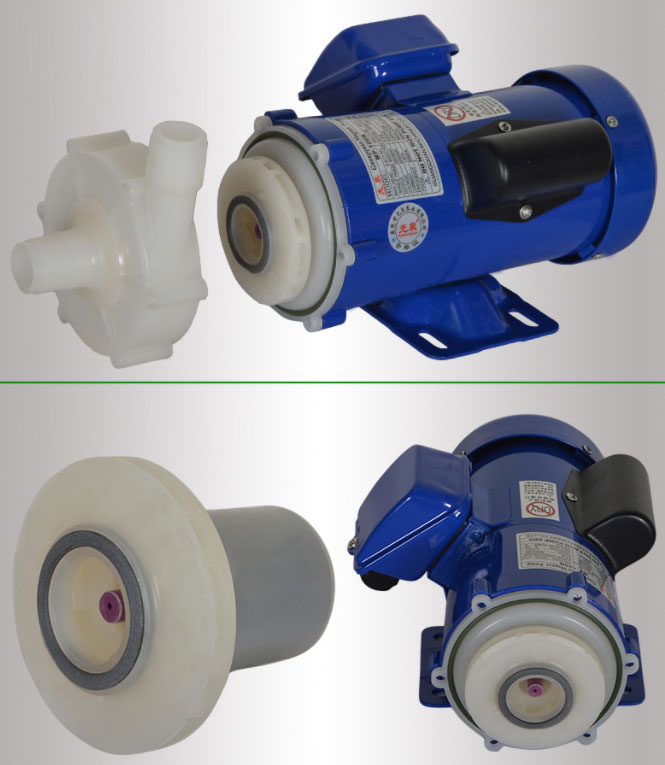

Corrosion Resistant Small Magnetic Drive Utility Pump

Magnetic drive pump is a high-tech product that applies the working principle of permanent magnet coupling to centrifugal pump.

The flow-passing parts of the magnetic pump are all made of fluoroplastic, with reasonable design, advanced technology, full sealing and no leakage.

Strong corrosion resistance and other characteristics, its performance has reached the advanced level of similar products in the world.

Magnetic drive pumps can continuously transport corrosive media such as acids, alkalis, and strong oxidants of any concentration.

The shaft seal is canceled, and the magnetic coupling is used for indirect drive, which eliminates the trouble of dripping and does not pollute the use site.

When working, the small magnetic pump has no friction. Therefore, the acid and alkali resistant pump has high efficiency and low power consumption. It not only avoids the impact on the pump when the motor is running, but also largely avoids the pump cavitation vibration from damaging the motor. In addition to high efficiency, this advantage also allows the pump to last longer.

The design of the small magnetic pump not only has the advantages of compact structure, beautiful appearance, small volume, low noise, and reliable operation of ordinary magnetic pumps, but also its flow-passing parts are all made of the best corrosion-resistant "plastic king" in the world.Therefore, the small magnetic pump can transport corrosive media such as acids, alkalis, and oxidants of any concentration (strong) without damage.

Strong wear resistance

Acid and alkali resistance

Good sealing

High stability

Strong magnet

High quality magnet, durable, low noise

Pump housing

Sophisticated design, beautiful appearance, acid and alkali resistance, special for chemical industry

Energy-saving motor

High temperature and corrosion resistance, energy saving and power saving, long service life

The small magnetic drive pump has excellent dielectric properties, chemical corrosion resistance, high and low temperature resistance, waterproof, non-stick, low friction coefficient, good self-lubrication and other properties.

At present, it has been widely used in chemical industry, electronics, electrical, aviation, aerospace, semiconductor, machinery, textile, construction, medicine, automobile and other industrial fields.

The magnetic drive pump body is completely sealed, and there is no shaft seal design, which will not cause leakage of chemical liquid.

For transportation process, electroplating, chemical industry, dyeing, waste water, waste gas treatment, etc.

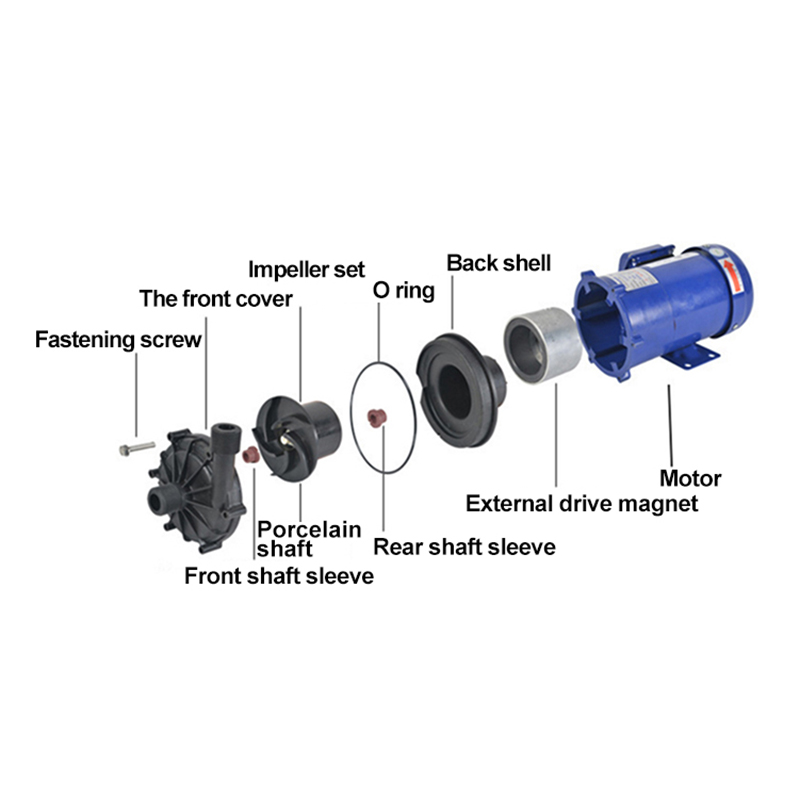

Back shell

The front cover

Impeller pack seal O ring

Fastening screw

Porcelain shaft

Rear shaft sleeve

Front shaft sleeve

motor

External drive magnet